Knowledge Carbon Metal Elbows and Fittings in Industrial Piping Devices

In industrial piping programs, elbows and fittings Engage in a crucial role in changing move course, connecting diverse pipe sections, and making certain a protected and leak-evidence program. Among the lots of different types of elbows and fittings offered, carbon steel elbow, butt weld elbow, as well as other carbon metal fittings are several of the most widely Employed in different industries, including oil and gasoline, petrochemical, energy technology, and drinking water procedure.

This text explores the attributes, styles, and programs of carbon metal elbows and fittings, using a deal with butt weld fittings, 90 diploma elbows, and A234 WPB elbows. We’ll also look at the production process of these parts and what will make a trustworthy elbow company.

What exactly is a Carbon Metal Elbow?

A carbon steel elbow can be a type of pipe fitting that permits for that alter of route inside of a piping process. These elbows are made from carbon steel, a fabric noted for its strength, sturdiness, and resistance to significant tension and temperature.

Carbon steel elbows arrive in several angles, the commonest becoming the 90 degree elbow, which turns the stream in a right angle. Other frequent sorts involve forty five degree elbows and 180 degree elbows for certain apps.

Butt Weld Elbow: A Protected Relationship

A butt weld elbow is a type of carbon steel elbow which is welded on the pipe finishes for a robust, seamless link. This process of becoming a member of makes certain negligible tension decline, lessened turbulence, and Increased move characteristics. Butt weld fittings are especially favored in higher-pressure systems due to their strong composition and long assistance existence.

Butt welding also gives a smoother interior surface, which is critical in purposes wherever fluid dynamics Engage in a major function.

Carbon Steel Fittings: Important for Piping Programs

Carbon steel fittings consist of a wide range of factors for example elbows, tees, reducers, and caps. They can be vital in customizing and adapting piping techniques for particular industrial requirements. Carbon metal is favored as a result of its mechanical properties, resistance to worry, and value-usefulness compared to chrome steel choices.

Whether you are working with large-temperature steam units or lower-temperature gas pipelines, carbon metal fittings really are a trusted selection.

Checking out the A234 WPB Elbow

The A234 WPB elbow is Just about the most commonly utilised fittings in carbon steel piping programs. The designation A234 WPB refers back to the content quality and manufacturing typical below ASTM A234 specification. WPB means "Wrought Pipe quality B", indicating a medium carbon material well suited for reasonable and significant-temperature applications.

A234 WPB elbows are usually out there in seamless or welded types. The seamless elbow is made from a single piece of metal with none welding joints, providing greater tension resistance and structural integrity.

Seamless Elbow vs Welded Elbow

The seamless elbow is known for its power and talent to take care of greater pressures, which makes it suited to critical programs. In contrast, welded elbows are much easier and more Price-productive to supply but can have limits in high-pressure environments.

The choice among seamless and welded elbows is dependent upon the precise prerequisites within your project, such as stress ratings, temperature, and price range.

Programs of Pipe Elbows in Market

Pipe elbows, Specially People crafted from carbon metal, are utilised extensively in a number of industries. Some regular apps contain:

Oil and gasoline pipelines – to navigate the pipe format in sophisticated environments

Energy plants – to move steam and h2o underneath substantial strain

Chemical processing – to convey corrosive fluids

Water procedure – for distributing h2o by way of remedy methods

The ninety degree elbow is perhaps the most commonly used because of its ability to alter the route of movement effectively.

How to Choose a Trusted Elbow Maker

When sourcing pipe fittings, it really is essential to settle on a dependable elbow producer. A quality company will supply:

Certified elements (including ASTM A234 WPB)

Precise Proportions and tolerances

Stress-analyzed and inspected items

Well timed shipping and responsive customer service

Seek out producers who give total traceability and adjust to Worldwide benchmarks including ASME, elbow manufacturer ASTM, and ISO.

The Role of Butt Weld Fittings in Technique Integrity

Butt weld fittings, including elbows, tees, and reducers, Engage in a key part during the structural integrity of a piping process. They're welded on to the pipe, forming a leak-evidence and mechanically powerful link.

In purposes exactly where the protection of your method is paramount—for instance refineries and nuclear crops—utilizing butt weld elbows and fittings makes certain superior reliability.

Summary

Comprehension the various different types of carbon metal fittings, such as butt weld elbows, seamless elbows, and A234 WPB elbows, is essential for engineers and industry experts working in piping methods. The correct fittings not simply strengthen move efficiency but additionally boost the protection and toughness on the process.

By partnering which has a dependable elbow company, you can ensure that your piping method is equipped with high-high quality pipe elbows that meet the demands of industrial overall performance.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Ralph Macchio Then & Now!

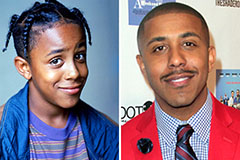

Ralph Macchio Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!